INTRODUCTION

MATERIALS AND METHODS

Location, plant material, and experimental design

Starch isolation

Total amylose and protein content

Pasting properties

Morphological studies by scanning electron microscopy

Amylopectin branch-chain-length distribution

Statistical analysis

RESULTS AND DISCUSSION

Climate conditions and rice yield

Total amylose and protein content

Pasting properties

Morphological studies by scanning electron microscopy

Amylopectin branch-chain-length distribution

CONCLUSION

INTRODUCTION

Rice occupies the largest areas worldwide and is one of the most important food crops, for over one-half of the world population, especially in Asian countries (Singh et al., 2005). However, rice consumption has been continuously decreasing due to westernization of the eating habits of Koreans (Mo et al., 2013). The reported average South Korean per capita rice consumption was 69.8 kg in 2012 and 60.8 kg in 2017 (Statistics Korea, 2017). Therefore, to expand the consumption of rice, processed foods which use wheat flour as a main ingredient are to be substituted by rice flour (Mo et al., 2013).

Rice flour is generally made through the wet-milling method (Suksomboon & Naivikul, 2006), but it leads to the generation a large amount of wastewater (Yeh, 2004). On the other hand, in the dry-milling method, cleaned rice grains can be directly ground to obtain rice flour. Moreover, no soaking is necessary in the dry-milling method, which is relatively simple and has a lower production cost compared to the wet-milling method. Given the considerable differences in the milling costs between dry and wet milling, the production of rice flour via dry milling using the most suitable rice varieties would significantly reduce the milling costs and promote the profits and overall development of the processed rice food industry (Kwak et al., 2017). The viviparous germination of rice flour varieties production has been reported to be disadvantageous due to long rainy periods, which results in lower rice yield and quality. Viviparous germination is induced and completed 30-35 days after the heading stage at an above-ground average temperature of 20°C for three days and affects negatively seed vigor, germination percentage and seedling emergence rate (Shon et al., 2014). The economic losses accrued are heavy because of the down-gradation of rice quality (Mohapatra & Kariali, 2016). Thus, to ensure the resources needed for mass consumption of rice flour by stable production, the development of rice flour varieties suitable for dry milling with low viviparous germination is necessary. Recently, exceedingly limited research exists on the morphological and starch properties of rice flour varieties and their appropriate transplanting dates for producing high-quality grain. In this study, we investigated three rice flour varieties with different genetic backgrounds to determine whether their starch is suitable for producing high-quality, dry-milled rice flour. Until now, ‘Seolgaeng’ has been the only variety used for the production of dry-milled rice flour developed in Korea. Nevertheless, three breeding lines of rice, ‘Hangaru’, ‘Suweon542’, and ‘Milyang317’, are considered promising candidates for rice flour varieties. ‘Milyang317’ has a round starch structure, is line with a high yield potential. On the other hand, ‘Seolgaeng’ and ‘Hangaru’ are rice flour varieties production with round starch structure (Kang et al., 2015). In South Korea, rice is transplanted from mid of May to end of June depending on the variety, availability of water, land, and labor for rice cultivation (Kim et al., 2016). Therefore, the objectives of the this study were to establish the optimal transplanting time considering the rice grain quality, and yield, and determine the effect of the different transplanting dates on the properties of the starch in the rice grains of the examined flour varieties production.

MATERIALS AND METHODS

Location, plant material, and experimental design

The study was conducted at the experimental fields of Gyeongsanbuk-do Agricultural Research & Extension Services. Three rice flour varieties, ‘Seolgaeng’, ‘Hangaru’, and ‘Milyang 317’, grown for 20 days in nursery beds, were transplanted on May 20, May 30, June 10, and June 20, respectively. The planting distance was 30 × 15 cm, and the amount of the fertilizer applied was N-P2O5-K2O = 9-4.5-5.7 kg/10a; fertilizer split application was performed at the basal-tillering stage-panicle initiation = 50-25-25 ratio (Kim et al., 2016). The rice grains were ground in a mixture grinder and stored properly at room temperature prior to their use in the actual experiment.

Starch isolation

Starch extraction from rice flour was conducted by the alkaline steeping method (Yamamoto & Shirakawa, 1999). Rice flour was steeped in 40 mL of 0.1% NaOH for 1h. Subsequent to each of above the extraction steps, the slurry was centrifuged at 1,300 x g for 10 min, and the supernatant was discarded and washed with 0.1% NaOH three times. The residue from the second NaOH extraction was neutralized with 0.1N HCl to pH 7.0, and then the residue was washed with deionized water, dehydrated, and powdered.

Total amylose and protein content

Amylose and protein content of each of the rice flour varieties was measured in triplicate using Cervitec grain inspector 1625 (Foss Analytical, Höganäs, Sweden) using 20 g of milled rice per sample.

Pasting properties

The pasting properties of the rice flour varieties were determined using a Rapid Visco Analyzer (RVA, Model 4, Newport Scientific, Sydney, Australia). Rice starch (3 g, 12% moisture basis) was weighed directly in the aluminum RVA sample canister, and deionized water was added to a total constant sample weight of 28 g. The temperature was set at 50°C, and the following 12.5 min, the test profile was run under the following conditions: the sample was held 50°C for 1.0 min, after which the temperature was linearly ramped up to 95°C for 7.3 min; then, the temperature was linearly ramped down to 50°C for 11.1 min and held at 50°C for 12.5 min (Kim et al., 2016). The peak temperature, peak viscosity, breakdown, final viscosity, and setback were determined and recorded.

Morphological studies by scanning electron microscopy

The morphology of the starch granules in the rice flour was investigated using a Scanning electron microcopy (SEM) (Model JSM-56000LV, JEOL) following the method of Chen et al. (2003). Purified starch samples were sputter-coated with gold and analyzed using SEM at an accelerated voltage of 15 kV. The images were observed at magnification from x 1,000 and to x 3,000.

Amylopectin branch-chain-length distribution

The chain length distribution of amylopectin was analyzed by using a high-performance anion-exchange chromatography system equipped with pulsed amperometric detection (HPAEC- PAD) according the previously reported method by Kasemsuwan et al. (1995) with modifications (Wang & Wang, 2000). The HPAEC system (Dionex DX500, Sunnyvale, CA, USA) consisted of the following components: a GP50 gradient pump, an LC20-1 chromatography organizer, an ED40 electrochemical detector, a CarboPac PA-1 guard column (4 x 50 mm), a CarboPac PA-1 analytical column (4 x 250 mm), and an AS40 automated sampler (Kim et al., 2016). The filtered (0.45-μm pore size) samples were separated with gradient elution from the 100% eluent A (150 mM NaOH) to the 100% eluent B (500 mM NaOAc in 150 mM NaOH).

Statistical analysis

Two-way ANOVA of the average values was performed to determine the significant level (P < 0.05) In addition, Duncan’s Multiple Range Test was also performed for the different treatments using Statistical Analysis Software, version 9.2 (SAS Institute, Cary, NC, USA). All results are presented as mean ± standard deviation (SD). All tests were run in triplicates.

RESULTS AND DISCUSSION

Climate conditions and rice yield

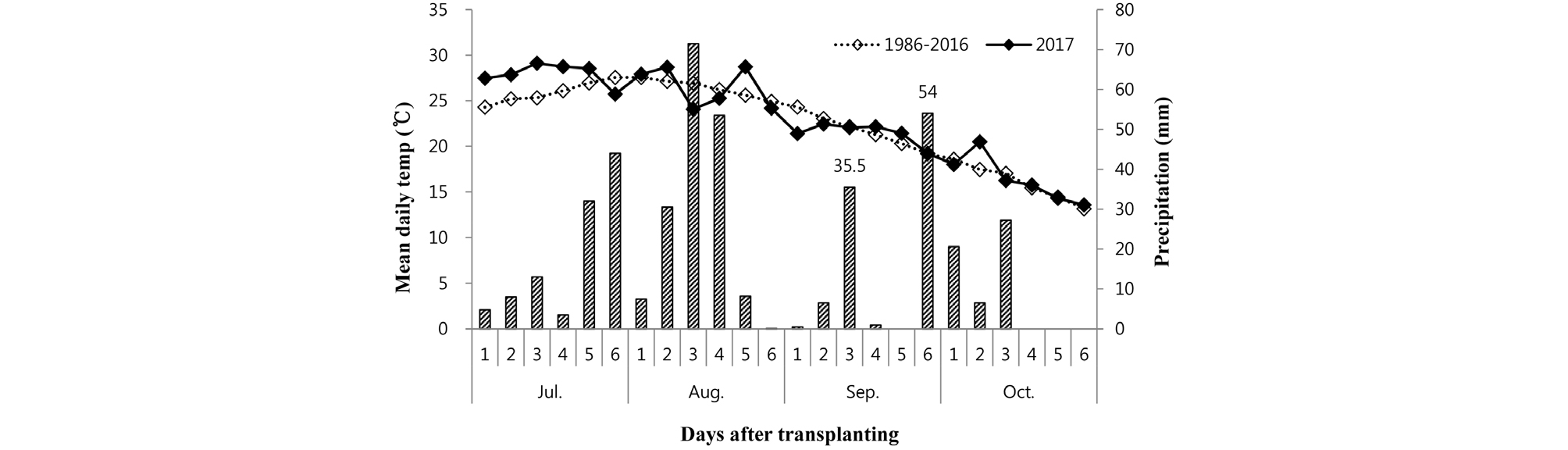

The changes in the rice yield, yield components, and viviparous germination rates in the three rice flour varieties transplanted on different dates are displayed in Table 1. The mean daily temperatures and the mean daily precipitation from heading to the harvest in 2017 were compared to those of the last 30 years (1986-2016), and the data are depicted in Fig. 1. The changes in the temperature during rice grain ripening stages are highly significantly correlated with crop growth and production. And if rice grain were not ripened under a lower temperature below 20°C environment, then ripening of rice mostly have been stable. During the grain filling of japonica rice, the optimum temperature for high grain yield and quality is well known to be within the range 21°C-23°C. The three studied herein rice flour varieties conducted in Daegu on different transplanting dates followed a stable dynamics of the ripening stage between 21°C and 23°C. However, the more frequent rainfall in September in Daegu during the grain ripening stage influenced the grain maturity and increased the probability to obtain a lower rice quality. More specifically, the rainfall which occurred at the high temperature during the ripening stage from Sept. 5 to Sept. 7 affected negatively the growth of the varieties for flour ‘Seolgaeng’ and ‘Hangaru’, causing a high viviparous germination rate. Viviparous germination is one of the major problems associated with rice cultivation that exerts a significant unfavorable impact, by lowering rice grain quality and yield. Therefore, the seeds of these varieties are unsuitable for use as seeds or food. Viviparous germination rates in the ‘Seolgaeng’ and ‘Hangaru’ transplanted on June 20 and June 10 were 6.1% and 8.5%, respectively. In contrast, the viviparous germination rates in ‘Milyang317’ on all transplanting dates were within 0%-0.2%, which were significantly lower than those of ‘Seolgaeng’ and ‘Hangaru’. The late transplanting date caused an increase in the rice yield in the three varieties for rice flour compared to those of early transplanting date. ‘Seolgaeng’ and ‘Hangaru’ varieties transplanted on June 20 produced the highest comparative grain yield, 582 and 523 kg per 10a, respectively. On the other hand, ‘Milyang317’ transplanted on June 10 produced the highest grain yield (728 kg per 10a). However, there was hardly ever difference in all dates. Difference in Grain ripening rate and ratio of brown by rough rice was fairly small among three varieties. The 1,000-grain weight in ‘Hangaru’ was higher than those of the two other varieties, but no significant difference was found in relation to the influence of the transplanting dates. The aforementioned results indicate that ‘Milyang317’, which is tolerant to viviparous germination, was the most suitable for use as a rice flour variety among the three examined varieties.

Table 1. Comparison of the yield components and rice yield for the three rice flour varieties transplanted on different dates.

Total amylose and protein content

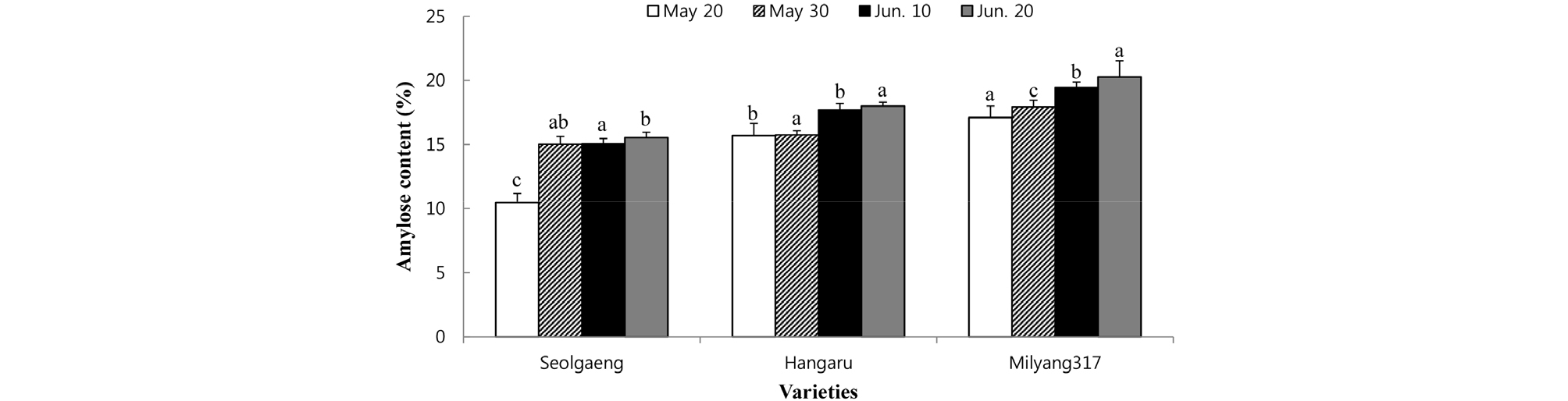

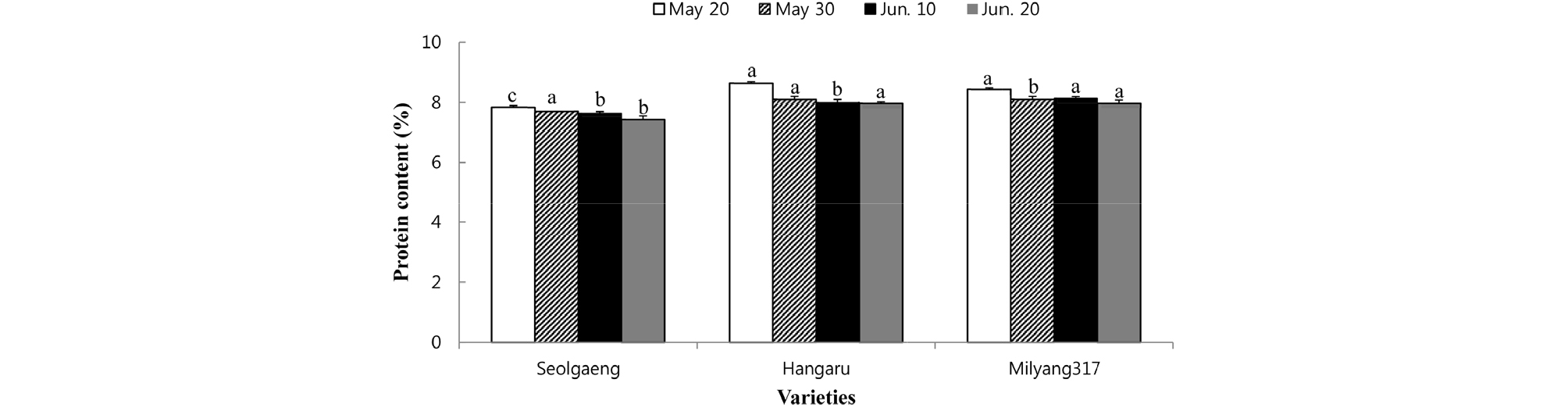

As can be seen in Fig. 2 and Fig. 3, the different transplanting dates caused changes in the amylose and protein contents of the three rice flour varieties. The relative amylose content of three rice varieties was in the following descending order: ‘Milyang317’ > ’Hangaru’ > ’Seolgaeng’. The amylose content in ‘Seolgaeng’, transplanted May 20, was 10%, which was 5%-10% lower than that established for the other dates. The amylose content in the two other varieties was 15%- 20%. Of note, the protein content did not show any significant differences in and among the three varieties, whereas the one of ‘Seolgaeng’ was slightly lower than those of the other two varieties. As illustrated in Fig. 2, the amylose content in the three varieties gradually increased along with the delay in the transplanting date, whereas the protein content decreased. Amylose and protein content are well known to be influenced by ripening temperature (Yamakawa et al., 2007). Previous studies revealed that the high ambient temperature during grain ripening results in lower amylose but higher protein contents (Adoration et al., 2012). In the present study, we found that the early-transplanted three varieties were subjected to higher temperatures, which were within the range 24°C-25°C, after heading, but the late- transplanted three varieties were subjected to lower temperatures within 21°C-22°C. It is noteworthy that the early- transplanted varieties matured at a higher temperature and had relatively lower amylose content but higher protein content than those of the varieties that matured at lower temperatures, showing a tendency that is similar to that established in previous studies.

Pasting properties

The pasting parameters, such as flour peak viscosity (PVa), hot-paste viscosity (HPV), breakdown viscosity (BD), cool- paste viscosity (CPV), setback viscosity (SB) and pasting temperature of three rice varieties of flours obtained from different transplanting dates are listed in Table 2. A similar tendency was exhibited in ‘Seolgaeng’ and ‘Hangaru’ for most of the parameters, except for the SB, PVa, HPV, and CPV values of two varieties, which were decreased on the delayed transplanting dates. Moreover, most of the values of the parameters, including PVa, HPV, CPV, BD, and SB of ‘Milyang317’ were also reduced. Notably, the pasting temperatures of ‘Milyang317’ obtained on different transplanting dates were significantly higher than the respective ones of ‘Seolgaeng’ and ‘Hangaru’, indicating the presence of a positive correlation with the amylose content (Fig. 2). It is generally known that the amylose content in rice is highly related to the pasting property of its starch. Rice grains that are with a low amylose content are usually sticky and with higher viscosity (Ayabe et al., 2009). Likewise, the results of this study showed that the amylose content was negatively correlated with the PVa, HPV, and CPV values under conditions of controlled temperature, whereas the protein content exhibited the opposite trends. By varieties, most of viscosity values of the ‘Milyang’ which found to be relatively higher amylose content were lower than those of the rest of two varieties. The above-mentioned results showed that the amylose content was positively correlated with the pasting temperature, and seemed to be related to the relatively ripening temperature as affected different transplanting dates. Notably, relatively higher pasting temperature were observed to be the most common for the three varieties one transplanting date, June 20, compared to those established on other transplanting dates. This result suggested that an increase in the cooking temperature and time would be required for the rice grain obtained from the plants with delayed transplanted dates.

Table 2. Influence of different transplanting dates on the pasting properties of starch from the three rice flour varieties.

Morphological studies by scanning electron microscopy

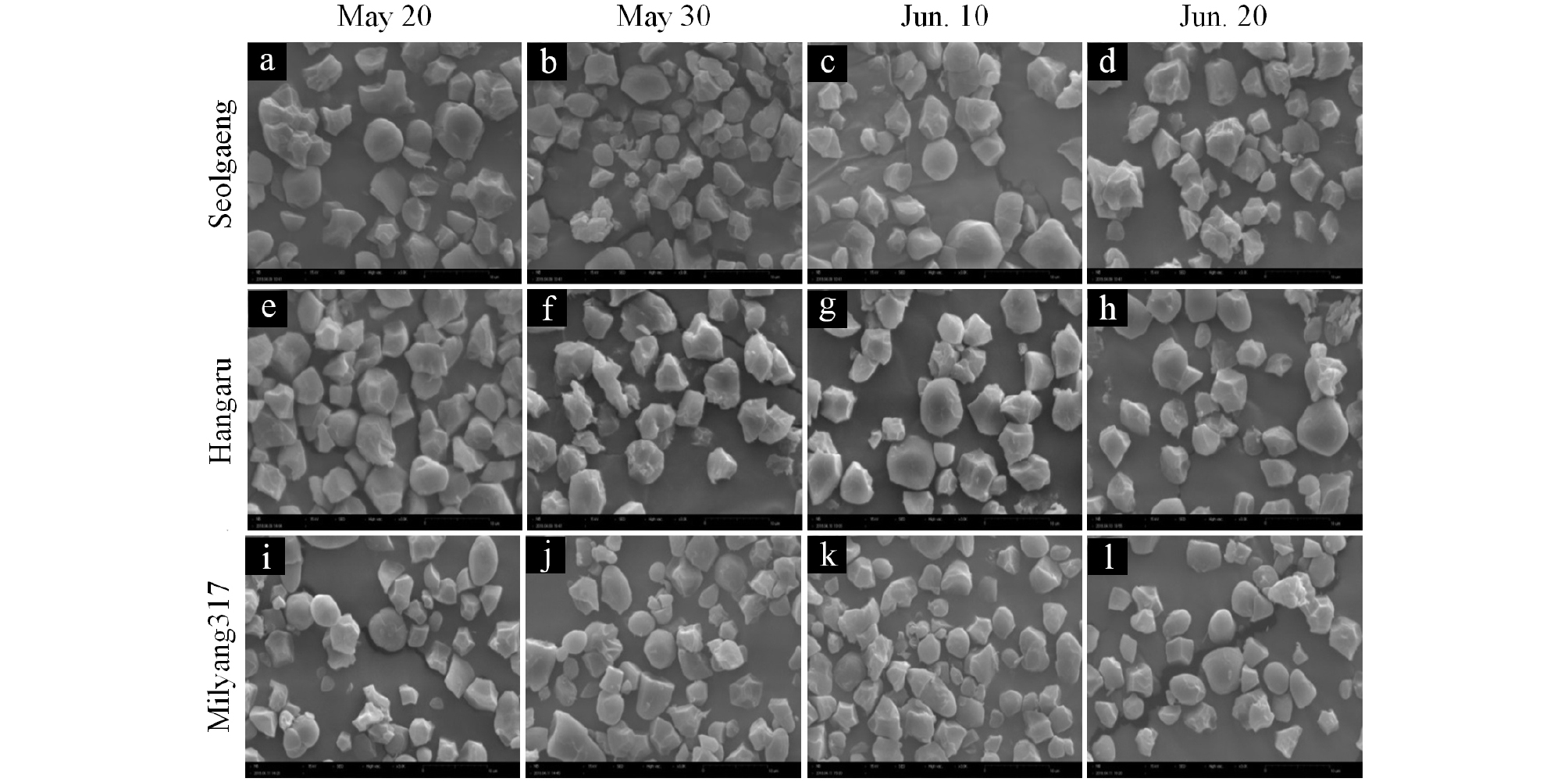

Scanning electron microscopy examinations showed that all studied rice flour varieties had slightly packed starch granules with irregular and rounded shape. However, no significant differences were found among the rice starch granule shapes and the granule sizes among the three varieties and different transplanting dates (Fig. 4).

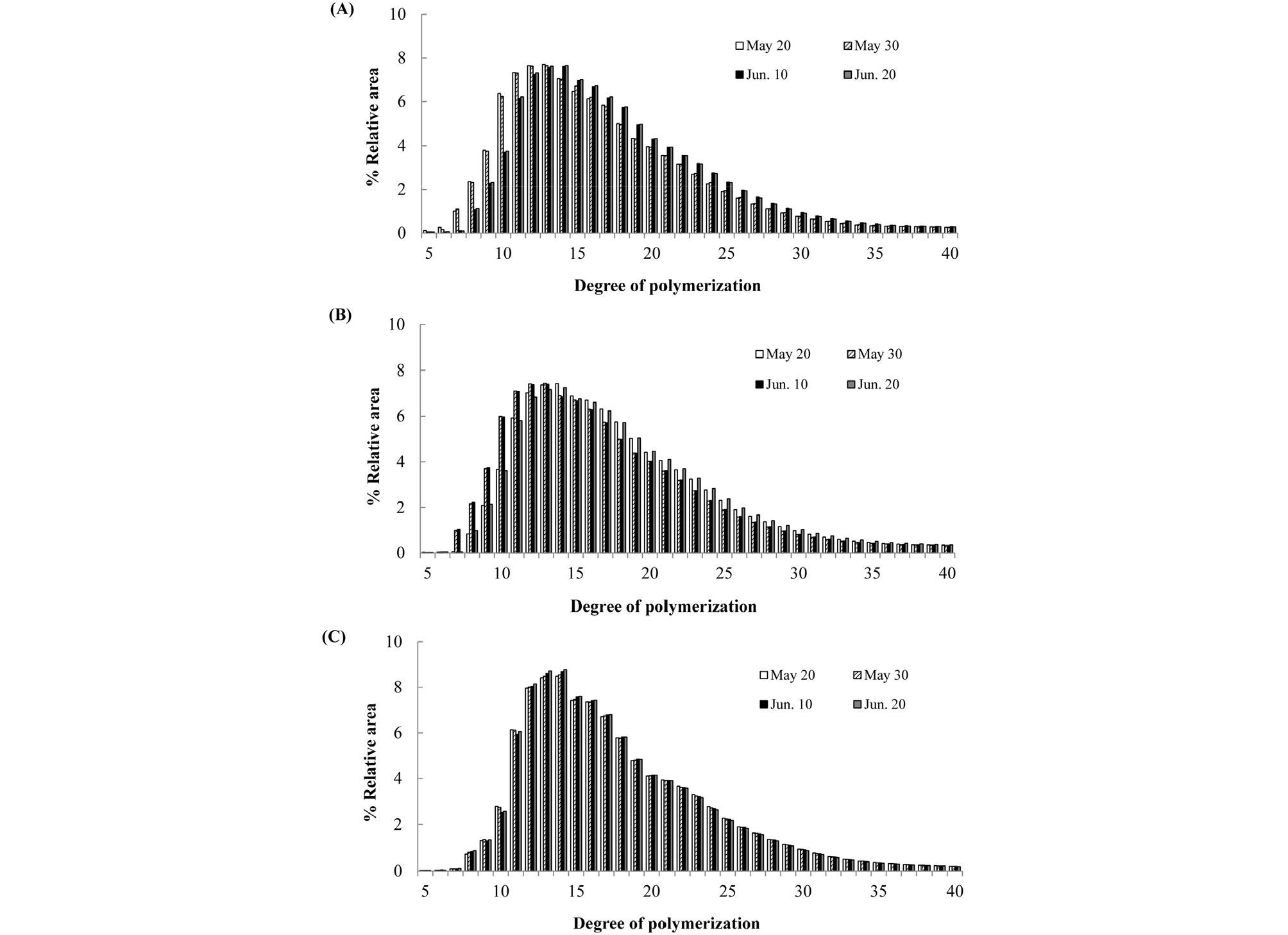

Amylopectin branch-chain-length distribution

As can be observed in Fig. 5, the amylopectin branch- chain length distributions of the starch in the grains of the three rice varieties were affected by the different transplanting dates. Accumulating evidence exists on the role of the fine structure of amylopectin in the physicochemical properties of rice (Yang et al., 2016). Generally, the higher ripening temperature, which affects the amylopectin molecules positively, is correlated with a higher proportion of long- chain amylopectin, whereas it is negatively correlated with the content of short-chain amylopectin. Furthermore, it has been reported that a variety which had more amylopectin molecules with a higher proportion of short chains was less sticky but had a harder texture (Chun et al., 2015). When it comes to the influence of the transplanting times, we expected that the early-transplanted varieties would exhibit a negative correlation with the proportion of the short-chain amylopectin because of the higher temperature during the ripening stages. However, the significant difference depended on being used for purpose of varieties. As shown Fig. 5, ‘Milyang317’ variety produced for high yield was different from ‘Seolgaeng’ and ‘Hangaru’ varieties produced for flour in the proportion of amylopectin chain length. ‘Seolgaeng’ and ‘Hangaru’ with greater amounts of the proportion of degree of polymerization 6-12 achieved influence of different transplanting dates compared to ‘Milyang317’. The amylopectin structure of ‘Seolgaeng’ transplanted on May 20 and 30 was characterized by a significant increase in the content of short chains with DP6-12 and a slight decrease in that of long chains with DP >= 15. In ‘Hangaru’, the proportion of DP6- 12 on May 20 was lower than that of ‘Seolgaeng’, whereas June 10 was higher than that of ‘Seolgaeng’. Meanwhile, the proportion of DP6-12 in the ’Milyang317’ was significantly lower than those of the other two varieties. The difference among the three varieties in the proportion of DP >= 35 was not significant. Gilbert et al. (2013) reported that starches with greater amounts of amylopectin chains with DP 6-12 had lower pasting temperatures than those with longer amylopectin chains with DP > 12 within the same botanical origin (Yang et al., 2016). As previously reported, ‘Seolgaeng’ and ‘Hangaru’ with greater amounts of short amylopectin branches were shown to be lower pasting temperatures. As above results, we could expect that the increase of amylopectin chain with short chain in ‘Seolgaeng’ and ‘Hangaru’ varieties transplanted early was related to lower pasting temperature, suggesting that an increase in cooking temperature and time would be not required.

CONCLUSION

To elucidate the influence of different transplanting dates on amylopectin branch-chain length and pasting properties of rice flour varieties, samples of rice flour obtained from plants on different transplanting dates were subjected to analysis of the starch, including properties, such as morphology, pasting characteristics, and amylopectin structure. In this study, we founds that the transplanting dates can influence most of the growth parameters and starch characteristics.

‘Seolgaeng’ transplanted on May 30 was with lower amylose content, lower viviparous germination rate, and amylopectin molecular with higher proportion of the short chain. In addition, there were no significant differences in the grain yield from plants transplanted on different transplanting dates. Similarly, ‘Hangaru’ transplanted on May 30 had lower amylose content, lower protein content, and amylopectin molecular with a higher proportion of the short-chain amylopectin. And at that time, it produced the highest grain yield and lowest viviparous germination rate. Considering the above-mentioned results, we suggest that the transplanting date in the cultivation of ‘Seolgaeng’ and ‘Hangaru’ in the Dae-gu area should be the end of May. ‘Milyang317’ showed a lower reduction in its yield and quality as it was unaffected by the different transplanting dates unlike ‘Seolgaeng’ and ‘Hangaru’. The results of the analysis of the amylopectin branch-chain length and pasting properties of rice starch showed a similar tendency regardless of different transplanting dates. Therefore we suggest that ‘Milyang317’ is more tolerant to various transplanting dates during the period from May 20 to June 20 than ‘Seolgaeng’ and ‘Hangaru’.